I agree to and consent to receive news, updates, and other communications via email from Lithium Ionic. I understand that I may withdraw consent at any time by clicking the unsubscribe link contained in all emails from [email protected].

Feasibility Study for the Bandeira Lithium Project

The FS for the Bandeira deposit demonstrates a technically simple and highly economic underground mining project.

See the May 29th, 2024, press release related to the Feasibility Study HERE.

*$USD unless otherwise stated.

HIGHLIGHTS:

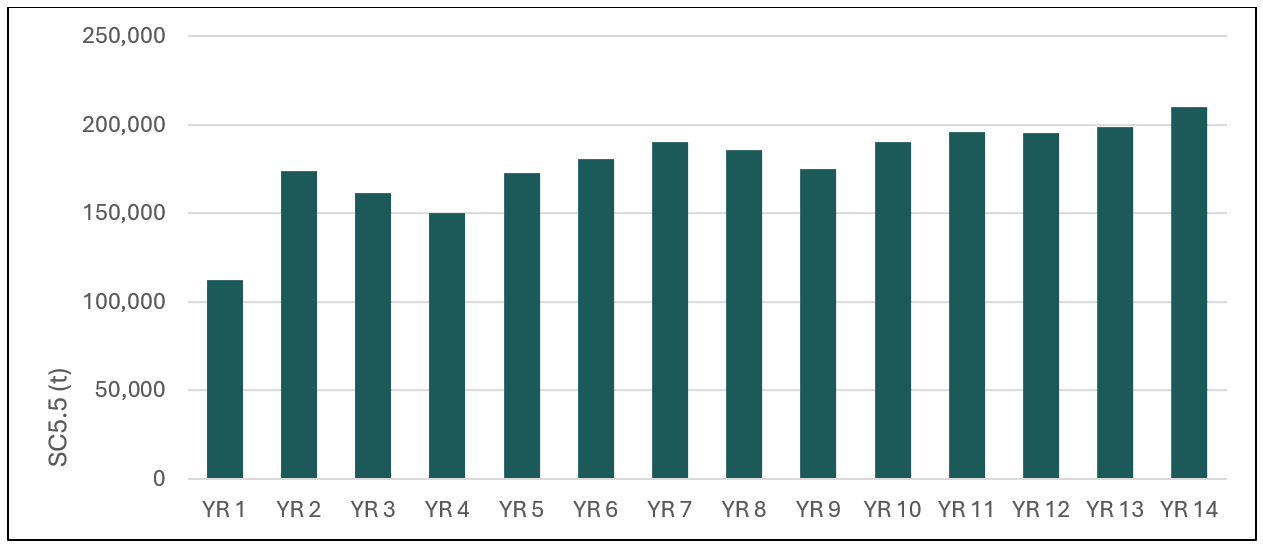

- Mine Life & Production: 14-year underground mining operation producing an average of 178,000t of high-quality spodumene concentrate grading 5.5% Li2O (“SC5.5”) per year based on Measured and Inferred mineral resources from November 2023 estimate.

- Strong Project Economics: After-tax net present value (“NPV8%”) of US$1.3 billion and after-tax internal rate of return (“IRR”) of 40% at average SC5.5 price of $2,277/t.

- Industry-leading Operating Costs: All-in LOM OPEX of $444/t of SC5.5

- Low Capital Intensity: Total capital expenditure (“CAPEX”) of US$266 million (including a 15% contingency) with after-tax payback of 3.4 years. LOM sustaining costs of US$ 81 million.

- Minimal Land-use Footprint: The development plan contemplates an underground mining operation with a simple processing circuit to optimize recoveries while minimizing the impact on the environment and local communities.

- Responsible Tailings Management: For safety and environmental reasons, the mine will utilize dry stacking waste disposal, which among other benefits will reduce water usage and facilitating site rehabilitation.

- Local Social & Economic Contributions: Total estimated taxes payable of $915 million, a peak local workforce of ~870 direct employees, and an estimated $677 million procuring goods and services within Brazil over the life of mine.

- Construction Permits on Track for mid-2024: The LAC license application submitted in November is currently under review by the state agency. Approval is expected in early Q3 2024.

SUMMARY OF KEY RESULTS AND ASSUMPTIONS:

| Project Economics | |

| Post - Tax NPV8 | $1.31 B |

| Post - Tax IRR | 40% |

| Pre - Tax NPV8 | $1.57 B |

| Pre - Tax IRR | 44% |

| Annual Revenue – LOM Average | $417 M |

| Average Annual After-Tax Free Cash Flow (after repayment of initial capital, years 4-14) |

$286 M |

| Payback | 41 months |

| Production Profile | |

| Total Project Life (LOM) | 14 years |

| Total LOM production (ore mined) | 17.2 Mt |

| Total SC5.5 production (LOM) | 2,493 kt (338.3 kt LCE) |

| Nominal Plant Capacity | 1.30 Mtpa |

| Average plant throughput | 1.23 Mtpa |

| Run-of-Mine grade, Li2O (mine diluted) | 1.16% |

| Average Annual Production of Spodumene Concentrate @ 5.5% Li2O | 178 ktpa (24.2 ktpa LCE) |

| Metallurgical Recovery (SC5.5% Li2O) | 68.9% |

| CAPEX & OPEX | |

| Initial Capital Costs | $266M |

| Sustaining CAPEX | $81M |

| Operating costs (FOB / t SC5.5) | $444/t |

| Economic Assumptions & Parameters | |

| Spodumene Concentrate Price (5.5% Li2O; LOM Avg) | $2,277/t |

| Exchange rate (USD:BRL) | $1.00: $5.07 |

| Discount Rate | 8% |

Project Location and Infrastructure

The Bandeira property covers 157 hectares, representing only approximately 1% of the Company’s large ~17,000 hectare land package in the northern region of Minas Gerais State, Brazil, within the renowned "Lithium Valley". This area is recognized for its significant concentration of lithium-bearing pegmatites, making it one of the most promising lithium-producing regions globally. The Project benefits from excellent local infrastructure, which is critical for the efficient development and operation of future mining activities.

The Bandeira site is well-connected via major highways, facilitating the transport of materials and personnel. The project site is approximately 570 kilometers from the port of Ilhéus in Bahia, which serves as a key logistical point for exporting lithium concentrate to international markets, including Shanghai, China. The proximity to Araçuaí provides access to essential services and amenities, enhancing operational efficiency.

A key infrastructure component for the Bandeira Project was secured in October 2023 through an agreement with Cemig Distribuição S.A. (“Cemig”). This agreement facilitates the construction and electrification of essential power infrastructure, including three kilometers of new transmission lines and a new substation adjacent to the future Bandeira mine and will ensure that the Project will be powered by low-cost, renewable hydroelectric power, aligning with the Company’s commitment to operating sustainably.

Mining Operations

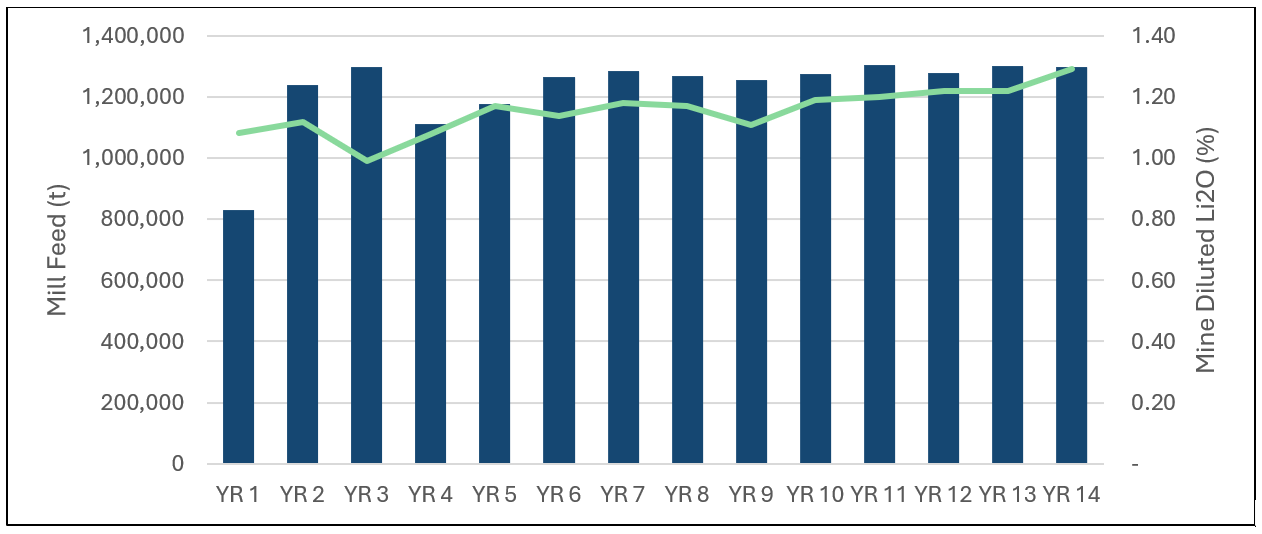

The Bandeira project is designed to incorporate dual underground mining operations, ensuring efficient extraction of its deposits. The primary orebodies, representing approximately 83% of the total deposit, will be mined using a bottom-up sublevel stoping method (Bandeira Sublevel Mine, or “BSL Mine”). Concurrently, the secondary southeast orebody, which comprises approximately 0.98 million tonnes, will be mined using the room-and-pillar technique (Bandeira Room and Pillar Mine, or “BRP Mine”). The annual mine production plan and the annual plant feed along with the Li2O grade below highlight the project's robust production capabilities.

ROM to Plant Feed and Li2O grade, %

Annual Production of Spodumene Concentrate grading 5.5% Li2O

Mineral Processing

The mineral processing flowsheet for the Bandeira project is designed to maximize lithium recovery and quality. It features a two-stage crushing circuit, which includes a Jaw crusher and a Gyratory Cone crusher, followed by dry screening classification. The coarse and mid fractions undergo ore sorting and Dense Media Separation (DMS) to produce a final SC5.5 Li2O concentrate. See the visual representation of the process flowsheet below.

The underground mine is expected to produce ore with an average Li2O grade of 1.16% over the Life of Mine (LOM), considering a mined dilution rate of 17.0%. The ore sorting process will enhance the ore quality by removing undesirable dilution materials, mainly schist, and non-lithium-bearing minerals such as feldspar and muscovite. This process improves the lithium oxide grade to approximately 1.50%, providing a higher-quality feed for the DMS while rejecting barren uneconomical waste. Based on Heavy Liquid Separation (HLS) bench scale test work completed by the Company, ore sorting and DMS pilot plant operations, the overall Li2O recovery is projected to reach 68.9%.

This efficient mineral processing approach ensures that we can maximize lithium recovery while maintaining the highest product quality. A higher quality chemical grade spodumene results in lower conversion costs therefore could potentially be sold at premium prices.

Bandeira Process Flow Diagram

Capital Costs

Initial capital costs for the Bandeira Project are estimated at $266 million, which includes a 15% contingency of $33.7 million. The sustaining capital over the 14-year mine life is projected at $81.4 million. A breakdown of the capital costs is presented below.

Project Capital Costs (CAPEX) Breakdown

| Initial CAPEX | $266.1M |

| Mine | $50.5M |

| Plant | $102.7M |

| Engineering Service | $26.6M |

| General Infrastructure & Others | $41.9M |

| Pre-operation | $10.8M |

| Contingency (15%) | $33.7M |

| LOM Sustaining CAPEX | $81.4M |

| SUDENE Federal Tax Incentive (%, reduction in Corporate Income Tax) | 75% |

*Discrepancies in the totals are due to rounding effects.

Operating Costs

The operating costs of the Bandeira Project are estimated to be US$64.30 per tonne of ore processed. Total operating costs are estimated at US$444 per tonne of 5.5% Li2O spodumene concentrate produced, placing it in the first quartile of the global lithium industry. A breakdown of the operating costs is presented below.

Bandeira Project Operating Costs (OPEX)

| Operating costs (per tonne of ore processed) | $64.3/t |

| Mining | $36.7/t |

| Processing | $24.6/t |

| SG&A | $3.0/t |

| Operating costs (per tonne of 5.5% Li2O spodumene concentrate produced) | $444/t |

| Mining | $253/t |

| Processing + Tailings handling | $170/t |

| SG&A | $21/t |

| Transportation costs to customer destination (Project Mine Site to Shanghai Port, China) |

$112.50/t |

*Discrepancies in the totals are due to rounding effects.

Project Economics and Sensitivities

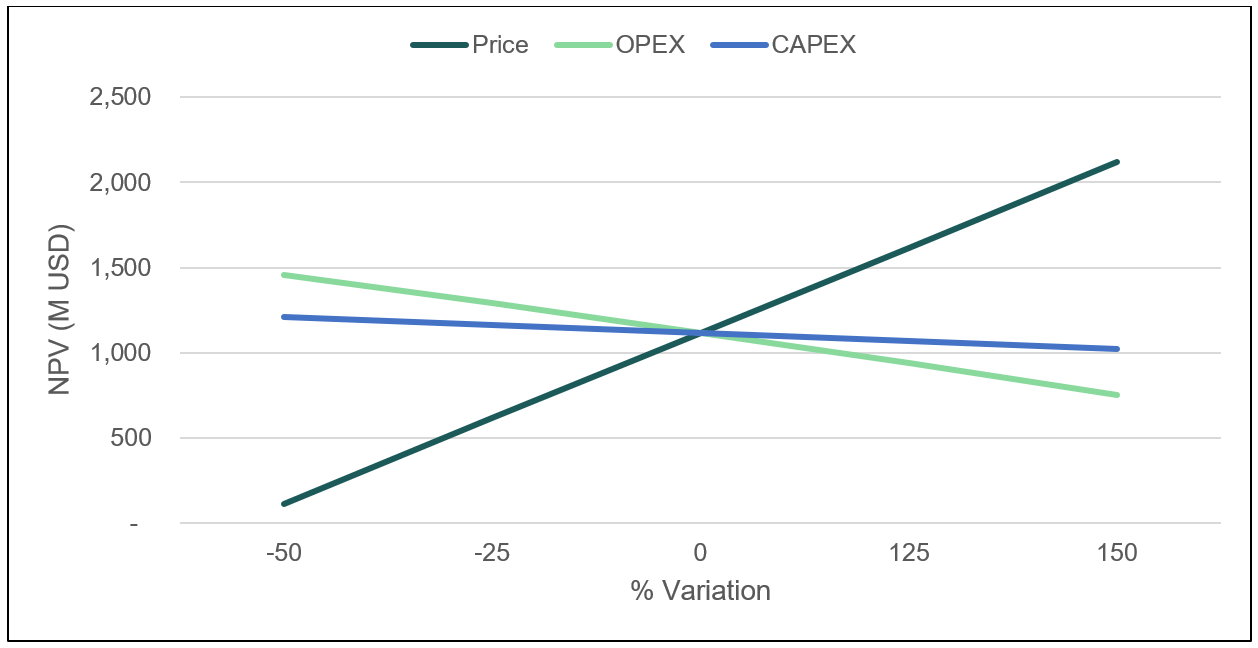

The after-tax NPV8 for the Bandeira Project is $1.3 billion and IRR is 40%, assuming a 5.5% spodumene concentrate (“SC5.5”) price of $2,277/t. At an elevated price of $3,416/t, the NPV increases to $2.4 billion with an IRR of 62%, underscoring the project’s strong potential to benefit from rising lithium prices (see sensitivity chart below).

Sensitivity analyses completed as part of the FS demonstrate that the Project's value is strongly influenced by the selling price of spodumene concentrate. While capital (CAPEX) and operational (OPEX) costs impact the Net Present Value (NPV), their effects are relatively minor compared to concentrate price fluctuations. Given the expected increase in lithium demand, Bandeira is well-positioned to capitalize on favourable market conditions and benefit from rising spodumene prices.

Sensitivity Analysis for Spodumene 5.5% Li2O price, CAPEX and OPEX estimation

After-Tax NPV and IRR Sensitivity to Spodumene Price

| Low Case | Base Case | High Case | |

| LOM Avg Spodumene Price (SC5.5) | $1,822/t | $2,277/t | $3,416/t |

| NPV | $864 M | $1.31B | $2.41B |

| IRR | 32.5% | 40.3% | 62.2% |

| Payback | 4.3 years | 3.4 years | 2.2 years |

Lithium Market Outlook & Spodumene Concentrate Price Forecast

A long-term spodumene concentrate price of US$2,277/tonne (5.5% Li2O grade) was used in the Feasibility Study. This long-term price forecast was obtained by Fastmarkets, one of the leading providers of global commodity pricing and market intelligence, in a report issued in April 2024.

The conservative spodumene concentrate selling price forecasts in the early years of the Bandeira mine life of $1,000-$1,600/t for the years 2026 to 2028 resulted in an increased payback period of the project compared to the PEA results from October 2023 (41 months compared to 14 months). Fastmarkets forecasts a higher long-term price based on strong demand and supply fundamentals, which is expected to benefit the Project's overall economics in the future.

Lithium has emerged as a critical component in the global energy transition, with an annual consumption growth rate exceeding 25% over the past four years. Despite the supply of lithium compounds surpassing demand in 2023, the demand remains robust due to the increasing market penetration of electric vehicles (EVs). According to industry expert reports from Fastmarkets, Benchmark Mineral Intelligence and the International Energy Agency (IEA), this trend is expected to continue as EV adoption accelerates globally.

Bandeira Mineral Resource Estimate

On April 12, 2024, the Company reported an updated NI 43-101 mineral resource estimate (“MRE”) for Bandeira of 23.68 million tonnes (“Mt”) grading 1.34% Li2O (783kt lithium carbonate equivalent, “LCE”) in the Measured and Indicated (“M&I”) category, with an additional 18.25Mt grading 1.37% Li2O (617kt LCE) in the Inferred category. This estimate was based on 233 drill holes, or 50,760 metres, drilled between April 2022 and March 2024.

The Bandeira FS proven and probable reserves, however, utilizes an NI 43-101 mineral resource estimate with an earlier data cut-off of November 13, 2023, which includes 186 drill holes (41,831 metres). This study mine plan is therefore based on a smaller estimate of 20.95Mt grading 1.35% Li2O (697kt LCE) M&I, in addition to 16.91Mt grading 1.40% Li2O (584kt LCE) Inferred (see Table 5).

The inclusion of the larger April 2024 MRE, as well as the additional drilling completed after the March 2024 data cut-off represents important future upside to the Project. The mine plan will be updated to incorporate the expanded mineral resource estimate in the next phase of project development.

The MRE was completed by independent Brazilian consultancy, GE21 Consultoria Mineral Ltda ("GE21").

Table 5: Bandeira Mineral Resource Estimate (base case cut-off grade of 0.5 % Li2O)

| Category | Resource (Mt) | Grade (% Li2O) | Contained LCE (kt) |

| Measured | 3.42 | 1.39 | 117.61 |

| Indicated | 17.52 | 1.34 | 578.92 |

| Measured + Indicated | 20.95 | 1.35 | 696.52 |

| Inferred | 16.91 | 1.40 | 583.53 |

Notes related to the Mineral Resource Estimate:

- The spodumene pegmatite domains were modelled using composites with Li2O grades greater than 0.3%.

- The mineral resource estimates were prepared by the CIM Standards and the CIM Guidelines, using geostatistical and classical methods, plus economic and mining parameters appropriate to the deposit.

- Mineral Resources are not ore reserves or demonstrably economically recoverable.

- Grades reported using dry density.

- The effective date of the MRE is November 13, 2023.

- Geologist Carlos José Evangelista da Silva (MAIG #7868) is the QP responsible for the Mineral Resources.

- The MRE numbers provided have been rounded to estimate relative precision. Values cannot be added due to rounding.

- The MRE is delimited by MGLIT Bandeira Target Claims (ANM).

- The MRE was estimated using ordinary kriging in 12m x 12m x 4m blocks.

- The MRE report table was produced using Leapfrog Geo software.

- The reported MRE only contains fresh rock domains.

- The MRE was restricted by RPE3 with grade shell using 0.5% Li2O cut-off.

- To convert percentage lithium (Li) to percentage lithium oxide (Li2O), multiply by 2.153; to convert Li to lithium carbonate (Li2CO3), multiply by 5.323. To convert a percentage of lithium oxide (Li2O) to lithium carbonate (Li2CO3), multiply by 2.472.

Project Advancement & Optimization Opportunities

Lithium Ionic is committed to progressing the Bandeira Project towards production, aiming to become a leading lithium producer in Brazil’s Lithium Valley. This goal is supported by the following ongoing activities:

Permitting Process and Government Engagement: The Company continues to advance the permitting process and actively engage with governmental agencies. The next major permitting milestone, the approval of the Licença Ambiental Concomitante (LAC), is expected in H2 2024.

Next Phase of Engineering: The Bandeira Project will proceed to the next phase of engineering, focusing on implementing the optimization opportunities identified during the feasibility stage. This phase will include an expanded mineral deposit, which among other positive impacts could potentially extend the mine life. Significant opportunities have also been identified to streamline capital and operating costs, enhancing overall efficiency and optimization of the Project.